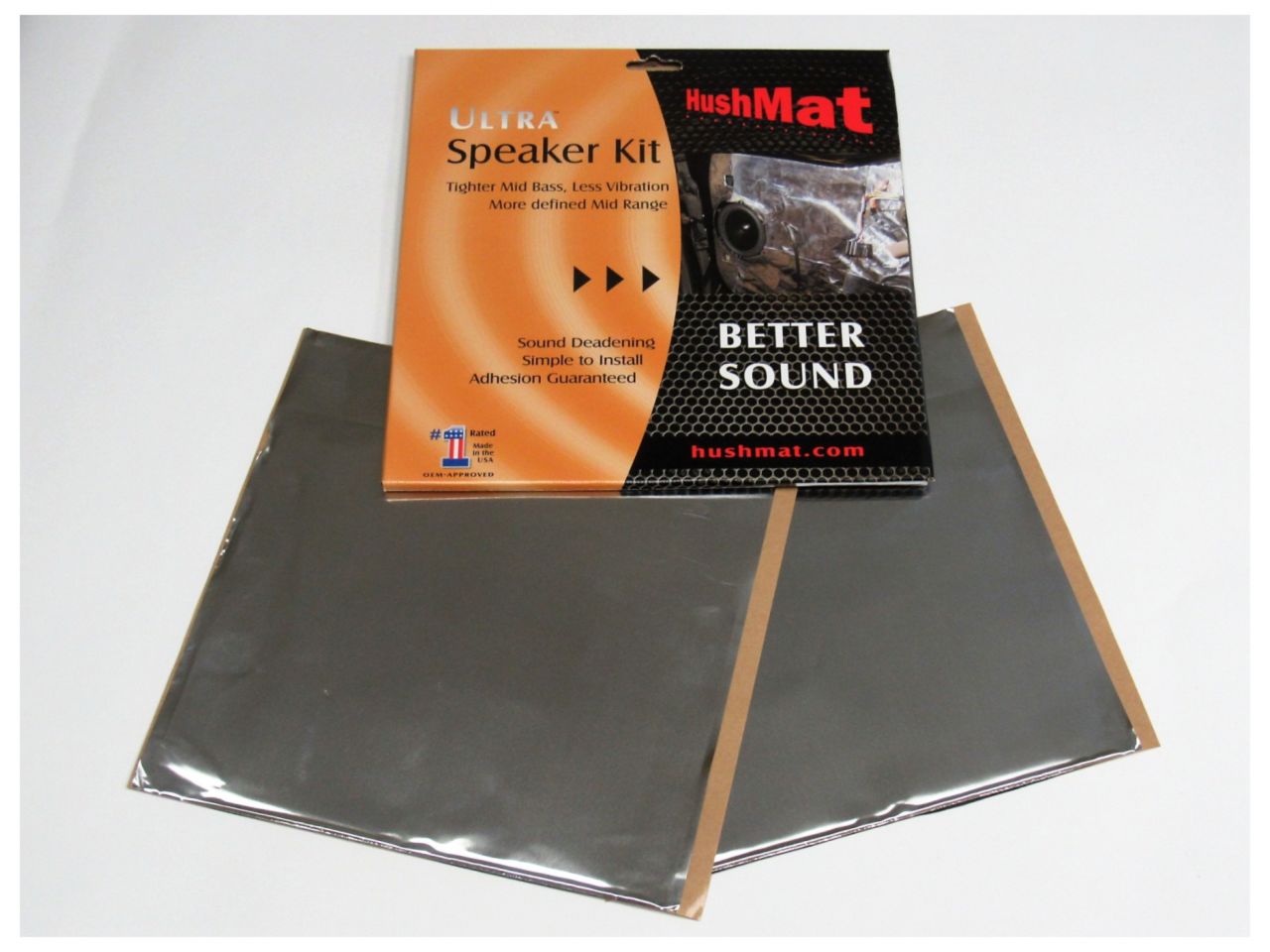

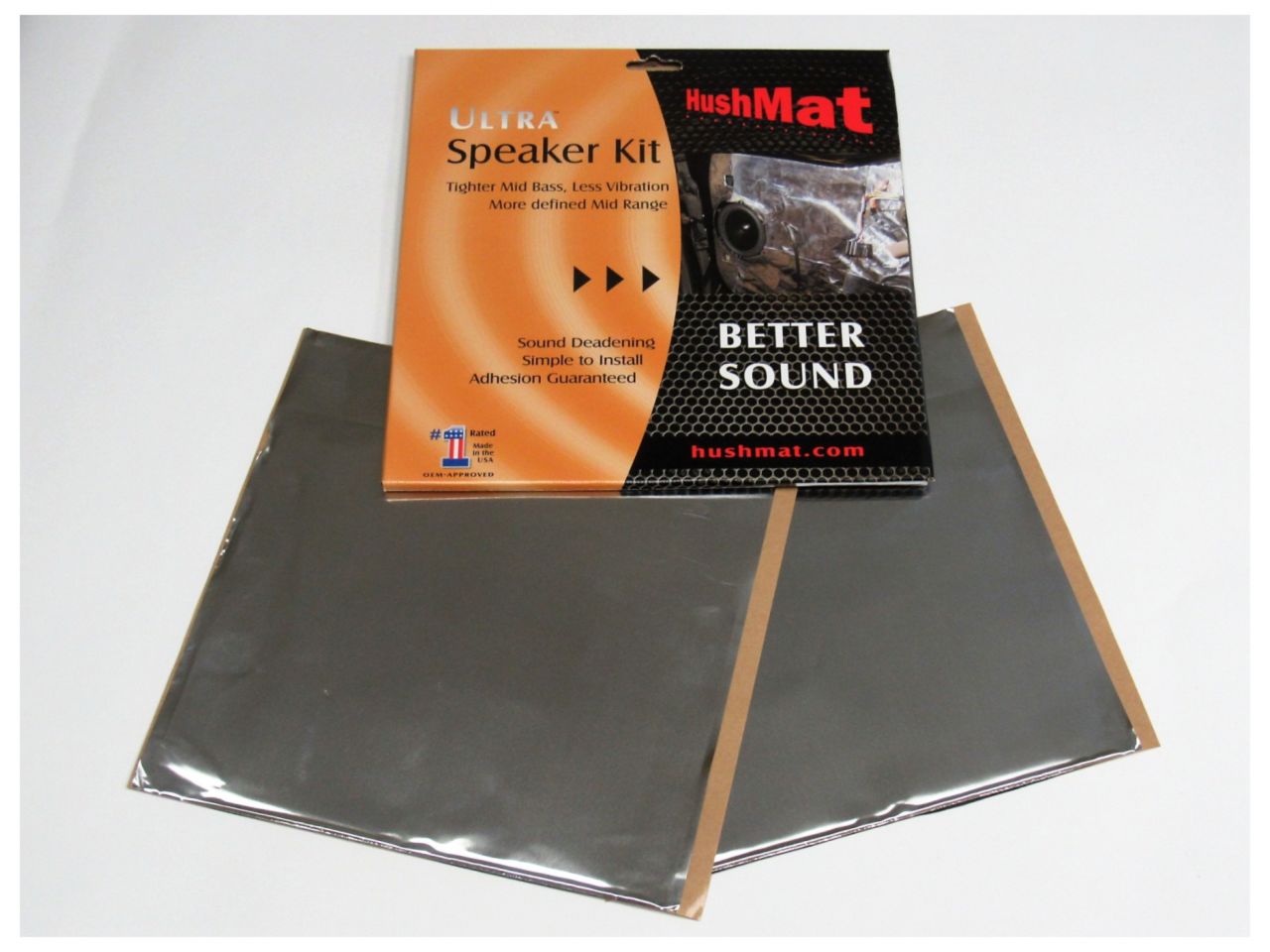

Hushmat Ultra Insulating/Damping Material Speaker Kit - (4) 6" x 12" - Silver

A pressure-sensitive, constrained-layer damper, which has excellent adhesion to many difficult to bond substrates such as oily cold rolled steel, automotive E-coat, primers and finishes, and many plastics including polypropylene. The aluminum foil constraining layer and specially formulated viscoelastic polymer layer combine to give effective vibration damping over a wide temperature range. Ultra is provided in rectangular or square sheets and can be hand-cut for special configurations.

Temperature resistant and will maintain adhesion through all automotive bake cycles including 288°C (550 degrees F) over-bake conditions. This allows its application at any stage of the production cycle. It can be applied to both pre-painted and top-coated metal surfaces. It is compatible with automotive coatings and will not contaminate spray operations. Superior adhesion characteristics provide excellent corrosion resistance.

The superior adhesive properties allow it to be used in horizontal, vertical or inverted applications. It has good conformability and can be applied on complex shapes.

HUSHMAT ULTRA is approved for many automotive specifications. Contact your Hushmat representative for details, and for design and custom application assistance.

TYPICAL PROPERTIES:

| COLOR: | Polymer - Black Backing - Aluminum Silver or Black |

| SPECIFIC GRAVITY: | 1.47 (approx. 0.47 pounds per square foot) |

| THICKNESS: | 1.5mm |

| HARDNESS: | 6.5 - 9.0mm. ASTM D-5 |

| R VALUE: | 7 |

| SHELF LIFE: | At least 6 months when stored at 40°C or less |

| TEMPERATURE RESISTANCE: |

Withstand a bake of 1 hour at 240°C with no deformation, sag, or flow when baked in horizontal, vertical or inverted positions. |

| COLD FLEXIBILITY: | Can be bent around 25mm. mandrel at -30°C with no cracking or loss of adhesion. |

| FLAMMABILITY: | Tested per FMVSS 302, Self-extinguishing and meets all aspects of the standard. |

| SAFETY: | Not considered a hazardous material. Care should be used in handling to avoid cuts from the foil. Gloves are recommended. The Material Safety Data Sheet is available upon request and should be read and understood before using this product. |

| PEEL STRENGTH: | Tested in 90° peel at a crosshead speed of 300mm per minute on a 25mm wide test specimen. Average load in Newtons is reported. |

Extract or delete HTML tags based on their name or whether or not they contain some attributes or content with the HTML editor pro online program.